Reducing risks in electronics production

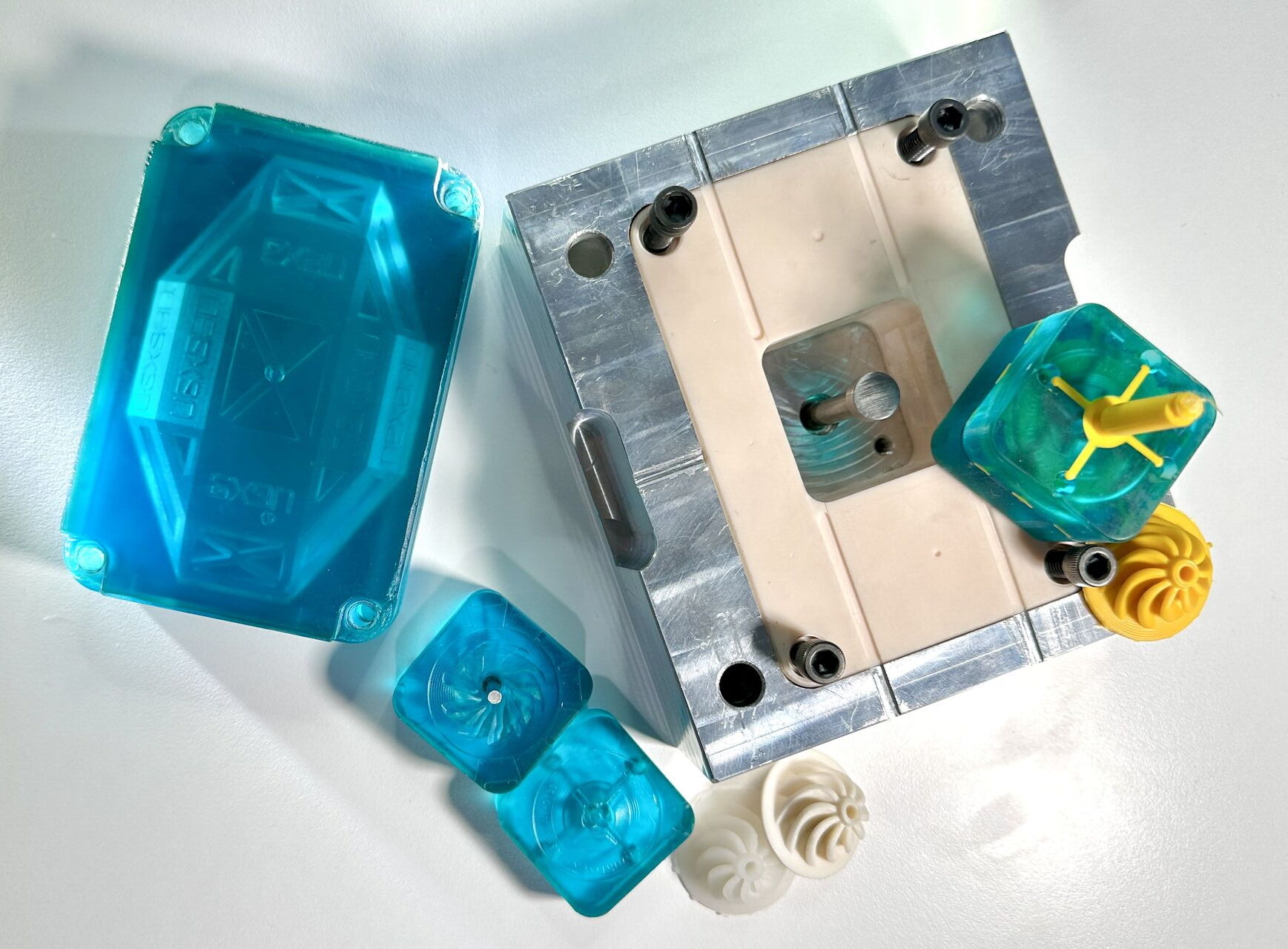

Reducing risks in electronics production Innovation is the be-all and end-all in the field of 3D printing. One of the most exciting developments in recent times is the introduction of the electrostatic dissipative resin xESD. This revolutionary material, combined with Nexa3D printers, helps electronics manufacturers reduce the risk of electrostatic discharge damage to [...]