How does Freeform Injection Molding (Fim) work – 3D printed injection molds

With Freeform Injection Molding, Nexa3D and Addifab enable the production of complex injection molded parts using 3D-printed tools. Experience unprecedented creative freedom in just a few days instead of several months. Freeform Injection Molding opens the door to faster, more cost-effective and more environmentally friendly product development than ever before.

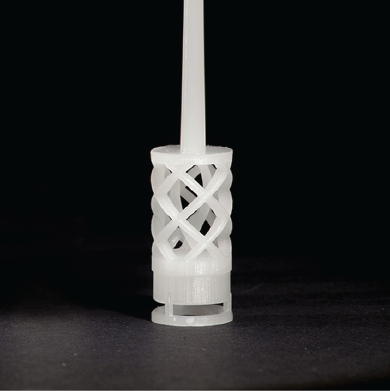

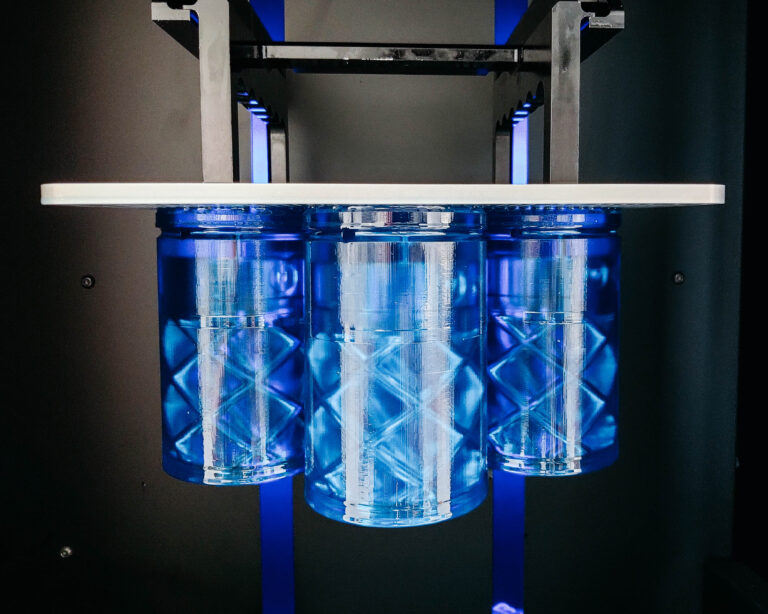

Print. Injection. Dissolve.

With free-form injection molding, you receive a tool-ready component in three short steps, which can be produced in an average of two days from CAD to injection-molded component.

” Freeform injection molding (FIM) is a transformative technology that enables fast and cost-effective innovation. FIM offers many invaluable benefits, including complete design freedom, functional realism, extensive material options and definitive physical properties that enable advanced R&D capabilities without the traditional limitations.”

Ky Layfield, Senior Packaging Development Engineer, the Coca-Cola Company

From CAD to a ready-to-use, 3D printed injection mold in hours instead of weeks

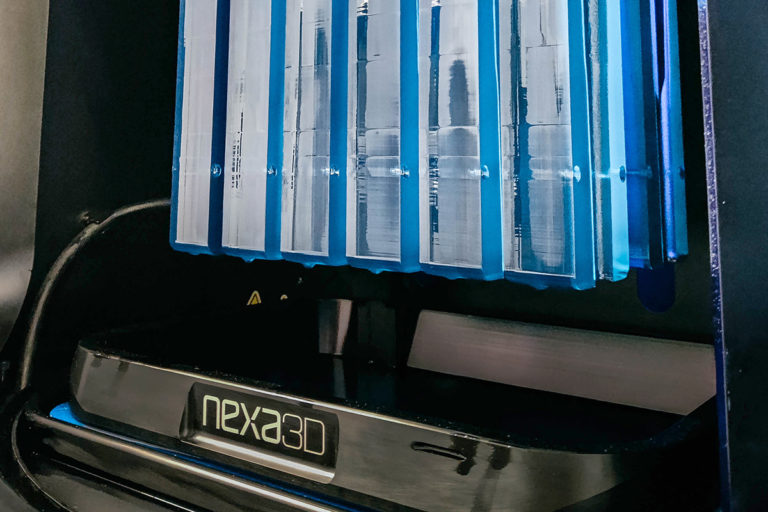

By combining the speed and throughput of Nexa3D’s LSPc printers with the flexibility of xMOLD plastic, you can go from design to complex tooling in a matter of hours. Speed up your design cycles, reduce your R&D costs and get your products to market faster – with digital toolmaking from Nexa3D.

[Download] Design guide for 3D-printed tools

Comprehensive design guidelines for freeform injection molding

Freeform injection molding combines the freedom of 3D printing with the reliability and mechanical performance of conventional injection molding. A complex tool is printed using a dissolvable xMOLD plastic that is compatible with the actual molding material to create final quality plastic prototypes and production parts – in hours and at a fraction of traditional tooling costs. This comprehensive guide will walk you through all the design considerations and guidelines to optimize your 3D printed tool design.

From CAD to production in just a few hours instead of weeks

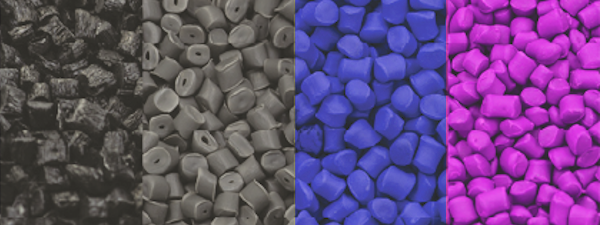

With digital tooling enabled by xMOLD resin, you can print real tools that are compatible with hundreds of current injection molding materials. Print traditional shapes for higher quantities or dissolvable shapes for “impossible” geometries.

Skip the machine workshop, simply press “Print and go”.

Please fill out our secure form to send a request.