Innovation “made by INNONET Kunststoff®” at the KPA in Ulm, 28.02. – 29.02.24

INNONET Kunststoff®, one of the largest company networks in southern Germany with concentrated expertise along the plastics value chain, will be taking to the stage at the popular KPA – Kunststoffprodukte Aktuell trade fair in Ulm in a few days’ time. Together with its network partners HoliMaker, Mexa3D and matriq, an international showcase of the latest technologies and materials will be presented.

Janet Rosenberger, INNONET Cluster Manager: “The plastics industry is facing new challenges, and we firmly believe that collective expertise and shared resources are the keys to the solution. Only together can we overcome the huge challenges we face as a plastics industry!”

matriq from Switzerland impresses with its DynamicMold® technology, which enables individual marking of plastic products during the injection molding process. A mold insert integrated into the mold ensures that each workpiece is provided with an individual marking that changes from shot to shot – including date and time, DataMatrix code or trademark. This not only offers the possibility of seamless tracking, but also eliminates the need for subsequent individualization of the workpieces. “With matriq, we want to make a valuable contribution to traceability and the implementation of the circular economy, relying on microtechnology to emboss 2D codes on plastic components in milliseconds during the moulding process using miniaturized heater arrays,” says Konstantin Kraut, Head of Sales at matriq. “The 8 mm mold insert is installed in the mold in a similar way to a classic pressure sensor and carries out the markings autonomously, i.e. independently of the machine,” adds Isabelle Herzog (technical sales) from matriq.

DM-qode mold insert from matriq for individual component marking (Ø8mm x 20mm)

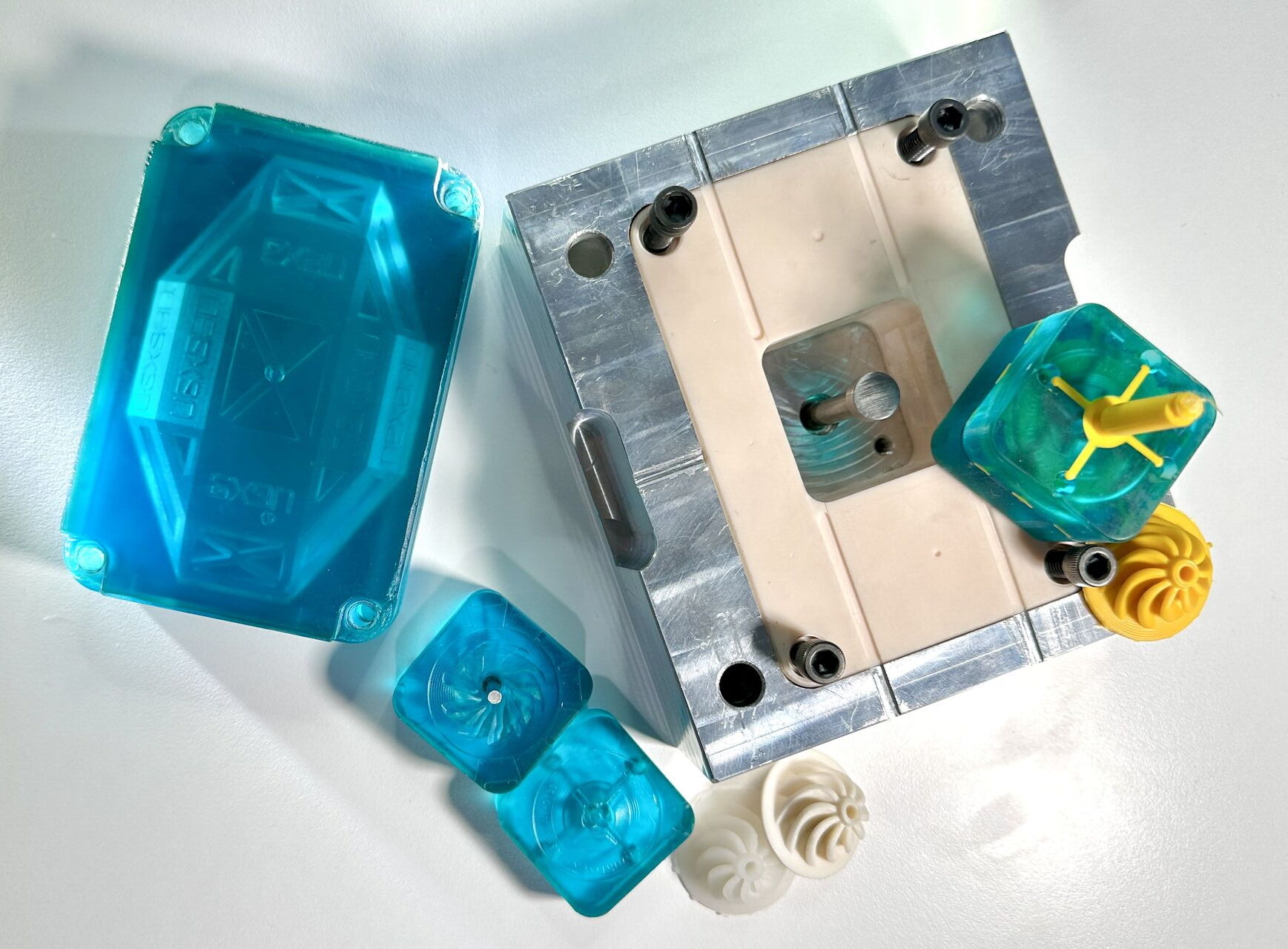

Mexa3D, the experts for industrial NEXA3D printers, will be presenting live 3D printing of injection molds. Jan Geese – Mexa3D: “Freeform Injection Molding (FIM) combines the best of additive manufacturing and injection molding. Instead of waiting weeks or months for your injection mold, you can now print it in just a few hours and test it immediately. The mold inserts are compatible with thousands of commercially available injection molding materials, including the one you will ultimately need for series production. This drastically reduces development times and iteration cycles. I am delighted to be able to present this ingenious innovation at the KPA.”

These pioneering technologies have been successfully combined under the management of Udo Eckloff, the exclusive importer of HoliMaker appliances in Germany and Austria. Experience live how a PP pellet is inserted into the insert demo mold using the HoliPress manual injection molding machine – a demonstration that will inspire you to use these technologies in series production. Udo Eckloff, general importer of HoliMaker products for Germany and Austria: “In a record-breakingly fast development project, we launched a pioneering collaboration last week.”

Triggered by a press release, Eckloff made initial contact with matriq on Monday. In a subsequent video conference, both partners explored the possibility of presenting the innovative insert in a demonstration process. Mexa3D enthusiastically declared its willingness to support the project on Tuesday. The ideas were put into action within a very short space of time: CAD data was exchanged on Wednesday and HoliMaker in France developed a customized tool that Mexa3D was able to print the next day. “This is undoubtedly the fastest development project that I have ever had the pleasure of supporting,” says Udo Eckloff enthusiastically.

Due to the international focus of the project, it was unfortunately not yet possible to carry out a test run. The trio will therefore be “flying blind” at the KPA, but are absolutely confident that they will be able to successfully present the innovative process. Aurélien Stoky, developer and CEO of the start-up HoliMaker SAS France, adds: “We have developed many concepts with customers and development partners in the past. But this international project, in which we were able to develop the tool design within a very short time and realize it through our cooperation partners, meets our goals exactly: To bring a product or process in the plastics industry to life through the use of HoliMaker and the use of 3D-printed injection molds and other components! We are looking forward to the reaction of our visitors!”

In addition to the live presentations of the technologies in Hall 1, Stand A11, INNONET invites you to a panel discussion on 22.02.2024 from 12:45 to 13:30: “Plastics connectivity: Creating maximum added value together along the plastics value chain” – together with INNONET partners AURORA Kunststoffe GmbH, priomold GmbH and ProPlas GmbH.

For more information about INNONET Kunststoff® and its partners, please contact us:

Mrs. Janet Rosenberger

Cluster manager

INNONET Plastics®/Plastics InnoCenter

Technology Center Horb GmbH & Co. KG

Geschwister-Scholl-Str. 10, 72160 Horb am Neckar

Phone: +49 (0)7451 62 3342

E-mail: rosenberger@innonet-kunststoff.de

www.innonet-kunststoff.de